Basket 0 (empty)

Basket 0 (empty) No products

Prices are tax included

Blog categories

Search on blog

Suspension repair with VIBRO ROOKS SYSTEM

Published: 14. 06. 2019 | Categories: Mode

Suspension repair with VIBRO ROOKS SYSTEM.

There are situations where the toe-in setting after the undercarriage has been repaired is not effective. Even in cars that did not suffer from great sheet metal damage. Some values, angles and distances are not normal. Why is this happening? More than one customer asks mechanics this question and receives evasive or inaccurate answers.

Of course, there are many reasons for this. Among them, attention should be paid to issues that depend only on the mechanic and his workshop, on the tools used for repairs. Other causes are independent of the mechanic and are influenced by the customer - such as the terrain and driving technique, car loads and regular inspections.

Chassis repairs are often associated with the need to replace worn parts, which are usually badly seized, rusty, dirty with mud, tar, salt and dust. These elements are very difficult to disassemble. Apart from the bearings and silent blocks, which have a tight fit, the assembly of the chassis components is light and smooth. Disassembly, however, causes many problems.

Mechanics have at their disposal many methods and technologies for disassembling the undercarriage components: the simplest and most common is punching, then punching combined with heating, heating with a torch or an induction electrode, freezing, mechanical pressing and hydraulic pressing, and finally impact pressing and hydraulic pressing with hammer. These techniques differ greatly from one another. Some are quite invasive and even harmful to the suspension components. These harmful techniques can cause significant deformation of the chassis, making it impossible to properly adjust the geometry.

The most aggressive and harmful techniques are hammering with a hand hammer and heating with a burner. The first causes considerable deformation of the structure, bends and changes in shape, the second causes thermal deformation of large surfaces, changes in metal structures, and burns the anti-corrosion layer and plastics. These techniques should be avoided and replaced with better ones.

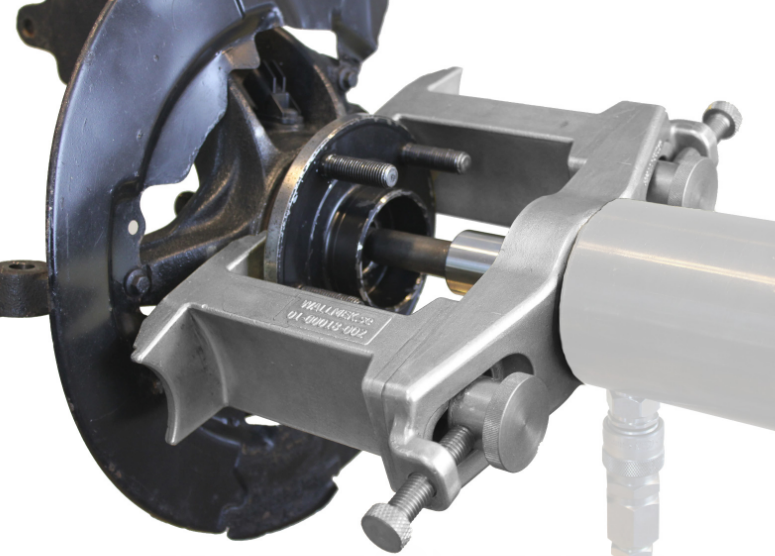

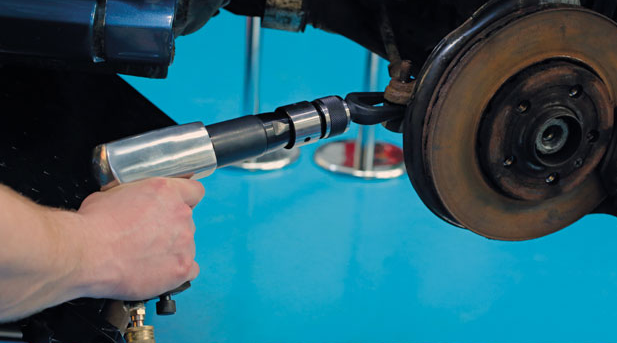

Which technologies are they? The best undercarriage repair technologies are related to extrusion, impact punching and hydraulic extrusion combined with impact. The last technology is used by the Swedish brand Wallmek (www.wallmek.pl) and it is used in the most severe cases and extremely sealed elements in all cars - from the smallest to huge cars and trucks. Wallmek is associated with a fairly high investment in a workshop. ROOKS VIBRO SYSTEM technology is characterized by high efficiency at a reasonable cost level. It is a technique based on squeezing and knocking out the baked elements using high frequency impact forces. These forces are directed to the place of the greatest resistance of the matter and lead to the fatigue of the foci and rust gangrene and their cutting. Due to the high frequency (2200 strokes per minute), the relatively low impact force of the pneumatic hammer causes the disconnection of elements that require the use of hydraulic presses.

VIBRO SYSTEM by ROOKS consists of a pneumatic hammer with an energy of 6.9 J, a working stroke of 98 mm and a frequency of 2200 / min, and various sets of impact tips for different applications. All bits are made of CrMo SCM490 steel and fit perfectly into the quick coupler of the jackhammer.

The VIBRO SYSTEM program consists of 8 elements:

| OK-04.0100 | Air hammer with quick coupler, VIBRO SYSTEM |

| OK-04.0101 | Impact extractor, 7-piece set, VIBRO SYSTEM |

| OK-04.0102 | Impact bolt extractor set, 5 pcs, VIBRO SYSTEM |

| OK-04.0103 | Lambda probe impact wrench 22 mm, VIBRO SYSTEM |

| OK-04.0104 | Chassis impact set, 7 pcs, VIBRO SYSTEM |

| OK-04.0105 | Impact puller for VAG knuckle bolt: A4 / A6 / Passat VIBRO SYSTEM |

| OK-04.0106 | Exhaust system strippers, 2 pcs, VIBRO SYSTEM |

| OK-04.0107 | Impact punch set, 6 pcs, VIBRO SYSTEM |

The advantages of the VIBRO SYSTEM for the undercarriage are as follows:

- High work efficiency

- Low cost of the entire system

- Protection of the undercarriage components against deformation

- Universal use

- Work directly on the car

Govoni manufacturer of specialist tools

Govoni manufacturer of specialist tools  How to remove a seized injector - VIBRO SYSTEM

How to remove a seized injector - VIBRO SYSTEM

0

0